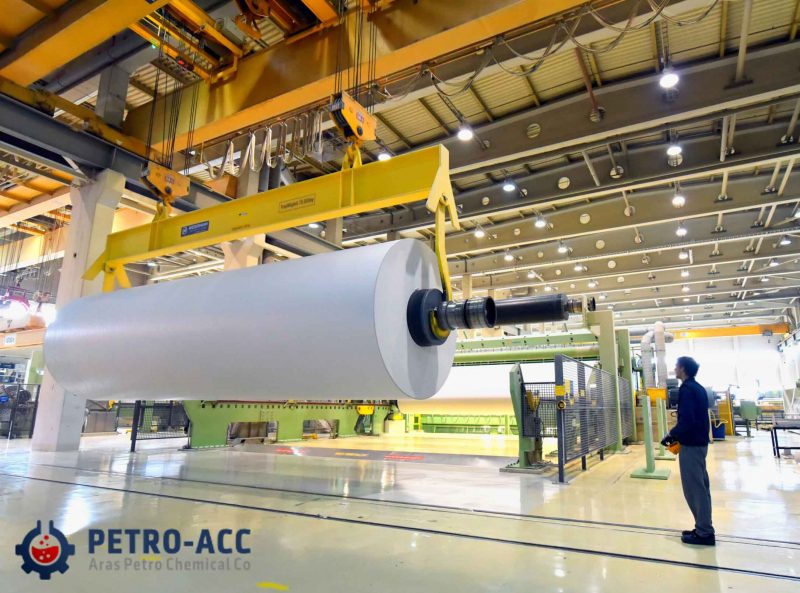

LABSA is primarily used in the production of household cleaning products such as detergents, soaps, and dishwashing liquids. It is also used in the production of paper and pulp as a wetting agent and emulsifier.

In paper production, LABSA can be added during the pulping process to help break down the wood fibers and separate them from other materials. It can also be added to the paper stock before the paper is formed, which helps to improve the uniformity and strength of the paper.

LABSA can also be used as a dispersing agent in paper coatings, which helps to evenly distribute pigments and other additives throughout the coating. This can improve the appearance and durability of the paper.

However, it is important to note that the use of LABSA in paper production can have negative environmental impacts if not properly managed. It is important to follow proper handling and disposal procedures to minimize any potential harm to the environment.

METHODS OF USING LABSA IN PAPER PRODUCTIONS

Linear Alkylbenzene Sulfonic Acid is a versatile chemical that can be used in various industrial applications, including paper production. In paper production, LABSA is mainly used as a defoamer, a wetting agent, and a sizing agent. Here are some methods of using LABSA in paper productions:

- Defoaming Agent: LABSA can be used as a defoaming agent in the papermaking process. It can help to reduce foam formation during the pulping process, which can improve the quality and efficiency of the paper production. LABSA can be added to the pulp slurry in the pulping process to reduce the amount of foam produced.

- Wetting Agent: LABSA can also be used as a wetting agent in the papermaking process. It can help to reduce the surface tension of the water and improve the penetration of the pulp fibers. This can improve the strength and quality of the paper produced. LABSA can be added to the water used in the papermaking process to improve wetting.

- Sizing Agent: LABSA can also be used as a sizing agent in the papermaking process. It can help to improve the water resistance and strength of the paper. LABSA can be added to the paper pulp in the sizing process to improve the properties of the paper.

It is important to note that LABSA is a strong acid and should be handled with care. The appropriate safety measures and handling procedures should be followed when using LABSA in paper production. Additionally, the amount of LABSA used in paper production should be carefully controlled to avoid adverse effects on the quality of the paper produced.

COSTS EFFECTIVE OF LABSA IN PAPER PRODUCTIONS

Linear Alkylbenzene Sulfonic Acid is commonly used in the paper industry as a wetting and dispersing agent, as well as a surfactant. Its effectiveness as a paper additive depends on several factors, such as the specific application and the properties of the paper being produced.

When considering the cost-effectiveness of using LABSA in paper production, it is important to consider both the benefits it provides and the cost of the product itself. LABSA can improve paper quality and production efficiency by reducing surface tension, enhancing ink absorption, and increasing the retention of fillers and additives.

However, the cost of LABSA can vary depending on factors such as the supplier, quantity purchased, and delivery method. It is important to compare the cost of LABSA to other potential additives and weigh the benefits against the cost to determine the most cost-effective option.

In addition, it is important to consider the potential environmental impact of using LABSA in paper production. LABSA is a chemical that can be harmful to aquatic life and the environment if not handled properly. It is important to follow proper safety and disposal protocols when using LABSA in any application.

Overall, while LABSA can be an effective additive in paper production, its cost-effectiveness will depend on the specific application and cost considerations. It is important to weigh the benefits and costs, as well as the potential environmental impact when making a decision about whether to use LABSA in paper production.

HOW LABSA DECREASE PAPER PRODUCTION COSTS

Linear Alkylbenzene Sulfonic Acid can be used in the paper manufacturing process to reduce production costs in several ways.

Firstly, LABSA can be used as a dispersant in the production of paper coatings. This helps to evenly distribute the coating over the surface of the paper, resulting in a smoother finish and reducing the amount of coating needed. This can help to lower the amount of coating required for a given amount of paper, which can ultimately reduce production costs.

Secondly, LABSA can be used as a wetting agent in the production of paper. This helps to improve the wetting properties of the paper pulp, allowing for better mixing and reducing the amount of time needed to achieve the desired consistency. This can help to reduce the overall time required to produce paper, which can lead to lower production costs.

Lastly, LABSA can also be used as a bleaching agent for recycled paper. By using LABSA as a bleaching agent, paper manufacturers can avoid the use of more expensive and harmful chemicals, leading to cost savings and a more sustainable production process.

Overall, the use of LABSA in the paper manufacturing process can help to reduce production costs through the improved coating, wetting, and bleaching properties.