Project Description

Oxidized Bitumen 90/40 would be one of the main bitumen products of PETRO-ACC that is used for Road construction and building construction. this grade of Bitumen has a special penetration due to its softening point range and follow of this Item has many uses in different industries.

| Name | Oxidized Bitumen 90/40 |

| Manufacturer | PETRO-ACC |

| Made By | Aras Petrochemical Company |

| Product Code | R 90/40 |

OXIDIZED BITUMEN 90/40 MSDS

Table scrolling horizontally

| Material Safety Data Sheet of Oxidized Bitumen 90/40 | |

| Product Name | Blown Bitumen 90/40 |

| EC NO | 265-196-4 |

| CAS# | 64742–93–4 |

| Color: | Black Brown |

| Odor: | the characteristic odor of bituminous products |

| Odor Threshold -ppm: | NA |

| pH: | NA |

| Boiling point °C: | NA |

| Hazards Identification |

|

| First Aid Measures |

|

| Fire-Fighting Measures |

|

Table scrolling horizontally

OXIDIZED BITUMEN 90/40 FEATURES

Oxidized Bitumen 90/40 Technical Details

This grade of Bitumen has too low penetration Although its softening point is lower than grade 115/15 In addition to penetration testing, there are tests used to determine Oxidized bitumen 90/40, including viscosity, shape, heat loss, and flash point. and the most important items are penetration and softening point.

According to the ASTM D36 method, the softening point of this grade of bitumen is between 85 and 95 ° C and the flash point is 250 ° C.

Oxidized Bitumen 90/40 Applications

This type of bitumen is used for Asphalt in road construction, Waterproof roofing felts, coating and insulation, and many other projects in different regions.

Oxidized Bitumen 90/40 Formulation

Oxidized Bitumen 90/40 is semi-solid Bitumen known by some formula according to application in industries such as:

Elementally, it contains 91% carbon and around 7% hydrogen, and other chemical contents are up to 1% sulfur, 1% nitrogen, 1% oxygen, and 2000ppm metals.

Bitumen Products are composed mainly of highly condensed polycyclic aromatic hydrocarbons.

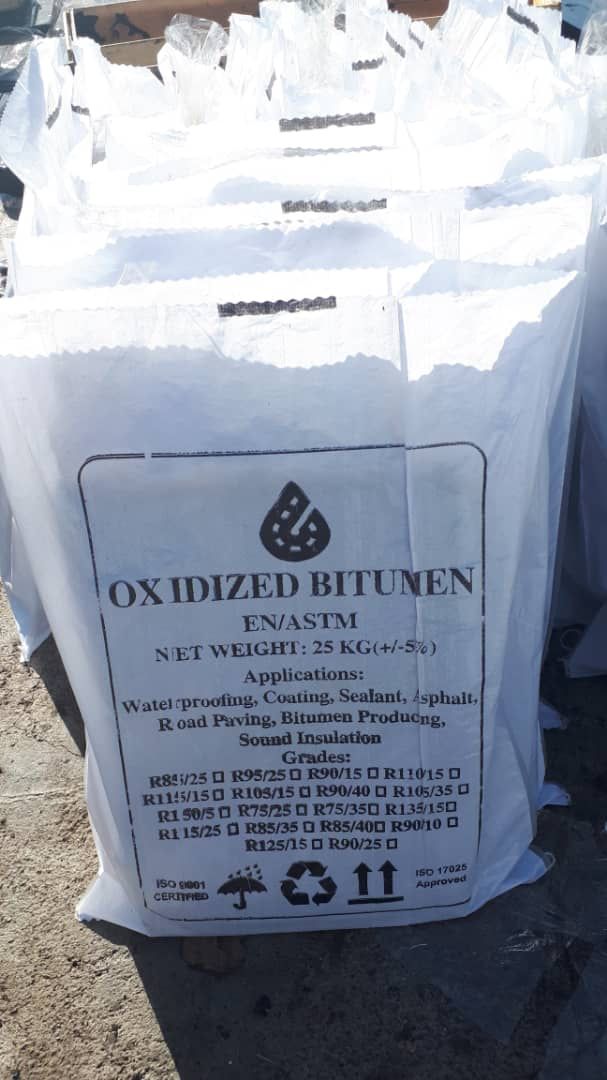

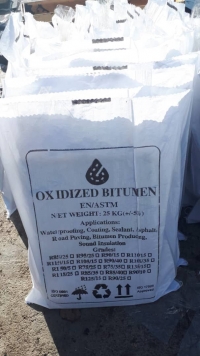

Oxidized Bitumen 90/40 Packing

Packing of this type of bitumen would be 25 kg poly bags or 25 kg carton boxes with pallets or without pallets.

OXIDIZED BITUMEN 90/40 SPECIFICATION

| SPECIFICATION | TEST METHOD | A.S.T.M. |

| PENETRATION AT 25 DEG C | 35-40 | D.5 |

| SOFTENING POINT DEG C | 85-95 | D.36 |

| DUCTILITY AT 25 DEG C CMS | 5.5 MIN | D.113 |

| LOSS ON HEATING PCT WT | 0.2 MAX | D.6 |

| FLASH POINT DEG C | 250 MIN | D.92 |

| SOLUBILITY IN CS2 PCT WT | 99.5 MIN | D.4 |