Project Description

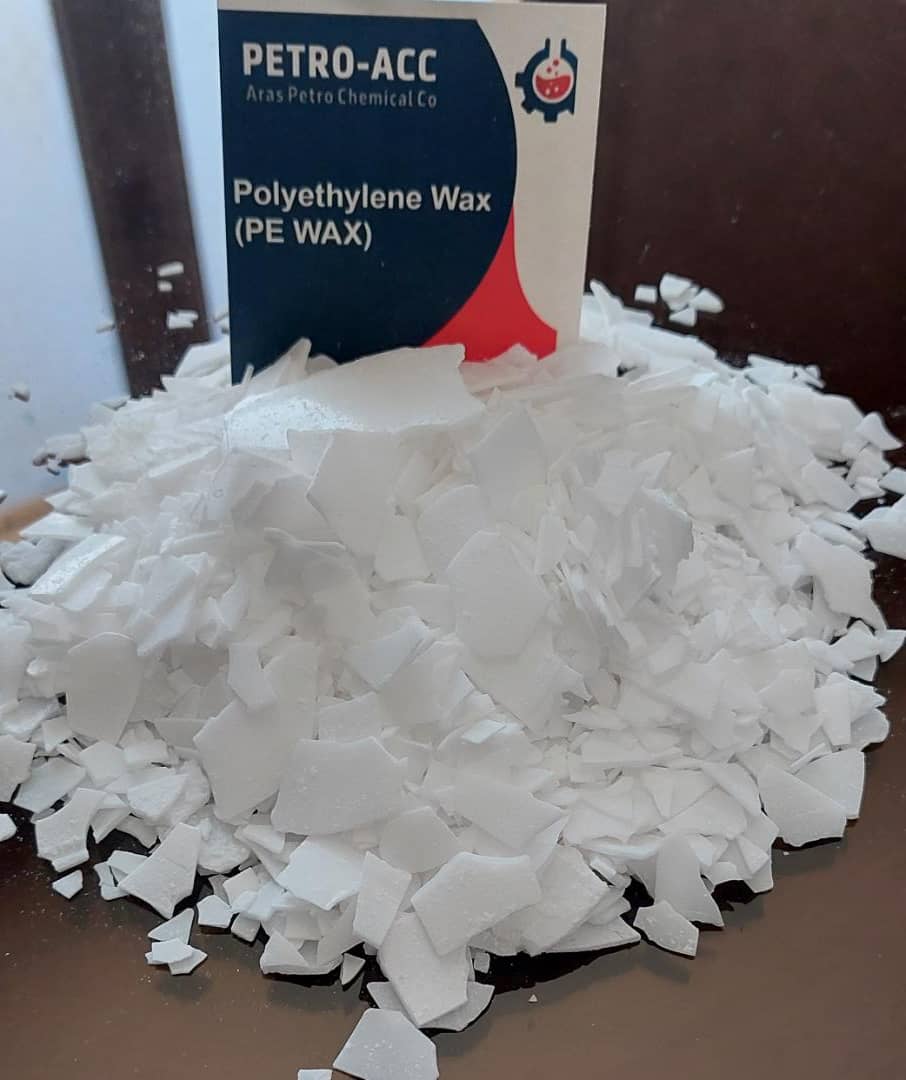

Polyethylene Wax (PE WAX) would be solid and Odorless with white color and it is a Polymer wax that would be in different modes and appearances such as Flake, Granules, Prills, LMP, and Lump.

Heavy Polyethylene wax has a linear structure and is produced with low and medium pressure. PE-WAX is one of the most common external lubricants.

| Name | Polyethylene Wax (PE-WAX) |

| Manufacturer | ARAS PETROCHEMICAL |

| Made By | PETRO-ACC |

| Product Code | PE110 |

POLYETHYLENE WAX MSDS

Table scrolling horizontally

| Material Safety Data Sheet of PE WAX | |

| Product Name | PE-WAX |

| Product Codes | PE110 |

| CAS# | 9002-88-4 |

| RTECS | Not applicable |

| TSCA | TSCA 12(b) |

| Synonym | High Density Polyethylene Wax, Polyethylene Wax, PE WAX , Polymer Wax |

| Chemical Name | Polyethylene Wax |

| Chemical Formula | (C2H4)n |

| Potential Acute Health Effects | Not expected to occur |

| Potential Chronic Health Effects | Not expected to occur |

| Eye Contact | If hot product splashes into eyes, flush immediately with clear cold water. Contact physician immediately. |

Table scrolling horizontally

POLYETHYLENE WAX FEATURES

Polyethylene Wax Technical Details

Ultra-low molecular weight polyethylene (average number of molecular weight Min less than 10,000) has the properties and functions like Wax. PE WAX would be produced through polymerization in high pressure with catalysts that contain Oxygen or polymerization in low pressure by using Ziegler, Natta catalyst or breaking chains way.

Most of the manufacturers of PE WAX refined the end materials of different grades of High-Density Polyethylene such as BL3, EX3, EX5, and 0035 by removing Hexane, Alcohol, and volatiles (moisture and oil) to make a high-quality and crispy PE WAX.

All PE WAX grades have the same structures but the final products would have different features because of different processes of production.

PE WAX is widely used in the purpose to reduce viscosity in different industries.

Functional PE WAXE has both physical and Chemical properties of PE WAX and oxygenated materials.

PE WAX has uses in different industries as dispersants of pigments, additives for inks, plastics productions, cosmetics productions, colors toner, and Adhesives industries.

Polyethylene WAX is a by-product material from BL3, EX5, f7000, 0035, and X3 of petrochemical that is made from first-class polyethylene lump.

PE WAX has less strength and flexibility in comparison to other polyethylene, but its resistance in front of chemicals and external pressures would be very high.

PE WAX would be a widely most useful type of polyethylene in the world.

PE WAXES according to their applications will have two types:

PE WAX using as a processing aid (PA) and lubricant (Used to achieve the quality and improvement of the production process of PVC & Polymer)

PE WAX as a basic material or additive will participate to improve and modify the properties of the final product.

The PE WAX quality would be under the effects of viscosity, melting point, density, and the ability to migrate to the surface and its color.

PE WAX flake color of PETRO-ACC would be completely white (not yellowish) and without black dots on it with below 3% of volatile materials.

PE WAX (HDPE) has a good function as a lubricant, via Ball Bearing Mechanism you can check and examine its lubricant property. In this mechanism PE- WAX particles migrate to the surface and as an interface will cover the surface and will prevent the material surface from contacting with the surface of the machines and molds.

Polyethylene Wax Applications

PE WAX according to the MFI (Melt Flow Index) range has different uses, most important applications would be as below:

- In the Production of plastic and injection molding industries

- In the Production of water and wastewater pipes and gas pressure pipes

- In the production of PVC pipes

- In the production of Cables wires

- Refined PE waxes are non-toxic and are used in food too, cosmetics, and healthy products

- In rubber industries as a lubricant

- In the Production of all kinds of candles, PE wax will increase the thermal resistance and hardness of candles

- In order to prevent oxidizing the metal surface during the coating process

- In the production of Master batch (Masterbatch) for better distribution of pigments and controlling the pressure in the process of production master batch.

- In asphalt as an additive

- In the ink and color toner industry

- In Hot melt adhesive, PE- wax by increasing the temperature of congelation without increasing viscosity will cause enhance (improve) the function of hot melt adhesive at high temperatures.

- In emulsions

Polyethylene Wax Formulation

The ultra-low molecular weight of polyethylene consists of ethylene monomer chains, and ethylene polymer would be the product of petrochemical companies. Polyethylene Formulation would be (C2H4)n

Polyethylene Wax Packing

PE- WAX of PETRO-ACC packing would be in different types:

20 kg polypropylene bags with pallet and shrink & in a Bulk mode in Big bags.

PE-WAX capacities for a different way of shipments would be as below:

20ft & 40ft containers for sea shipment:

20ft FCL: 13 MT/20 kg bags with pallets

40ft FCL: 25 MT/20 kg bags with pallets

The capacity of a Full truck: 25 MT

POLYETHYLENE WAX STORAGE

PE-WAX must be storage in a dry and cool place with temperatures between 0 °C till 40 °C.

PE-WAX should be protected from heat and direct sunlight (Direct sunshine will cause the color of PE-WAX to change and become yellowish)

POLYETHYLENE WAX SPECIFICATION

| PROPERTIES | Result | Unit |

| Color | White | – |

| Appearance | White Flakes | – |

| Chemical Formula | (C2H4)n | – |

| Molecular Weight | 1000 – 2000 | g/mol |

| Flash Point | 137 | ℃ |

| Drop Melting point | 100-115 | ℃ |

| Softening Point | 95 – 115 | ℃ |

| Penetration Hardness | < 15 | dmm |

| Density | 0.95 – 0.98 | gr/cm3 |

| Viscosity @140 ℃ | 10-40 | Cps |

| Peak Chain Length (SEC) | 35 – 45 carbon atoms | |

| Homogeneity Index Mw/Mn | 1.5 approx. | |

| Polyethylene wax | ≥ 98% | – |

| Water | < 2 % | – |

Hello sir

We are introduce ourselves as distributor of pe wax in India from 15 years

As per your site your company is major supplier of pe wax request you to kindly send quote

We look forward for best quote considering competitive scenario

Best regards

Aditya