PE WAX (Polyethylene wax) is a low molecular weight polyethylene that is well known as Polymer Wax.

Polyethylene Wax has most useful Wax features such as: Low molecular weight, Low viscosity, High hardness, and High melting point. These features of PE WAX made it good choice as an additive and Lubricant in a lot of industries.

In below table some features of Polyethylene Wax compared with Paraffin Wax:

| Item | Paraffin Wax | Polyethylene Wax |

| Physical Appearance | – Colorless or white solid in slab, granule, liquid form.

– Oily and soft – Insoluble in water |

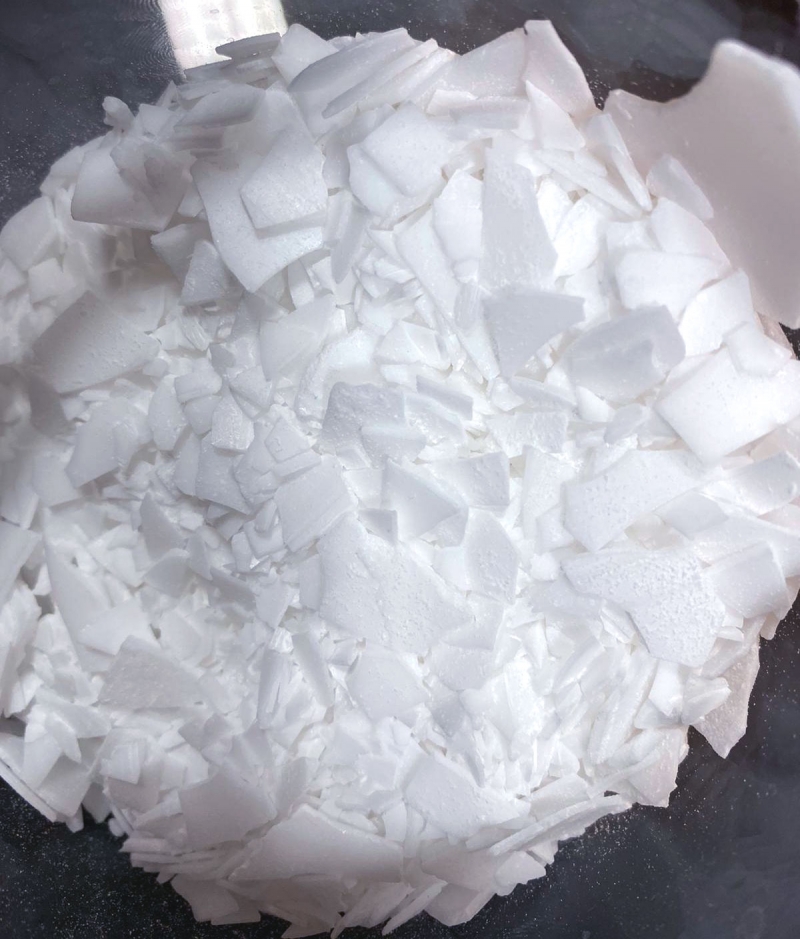

– White solid in flake, powder, granule and bead form.

– Completely crisp and dry – Insoluble in water , soluble in oil |

| Grades | According to refined Levels there are below grades :

– Fully refined – Semi-refined – Raw Paraffin Medical grade of paraffin wax Industrial grade of paraffin wax |

According to below features PE WAX would be different from each other in usage and function :

-Molecular weight (would be 300 ~10,000) -Ethylene monomer chains (chain branching of the final polymer) -Polymer composition |

| Melting point | 47 – 69 °C (115 and 154 °F) | Low melting point , about ~150°C |

| Density | About 900 kg/m3 | About 0.89-0.95 gr/cm3

(ASTM D 1505 (2018)) |

| Oil content | In different refining process levels, the Oil content would be between 0.5 till 7% Oil content. | Volatile content and oil content below 3% |

In production of candles both of them (paraffin wax and less than 3% polyethylene wax) will use. But Paraffin wax 1-3% oil content would be main material for producing candles.

Polyethylene Wax would be used as additives to make surface of candles so glossy and shiny without stains.

PE WAX also will increase candle hardness and some candles after production will be melt in room temperature easily, in such case by adding polyethylene wax and stearic acid to candle it will increase hardness and Strength of candle.

PE WAX will increase thermal resistance and burning time of candles too.

Hi, i believe that i saw you visited my website so i came to

return the choose?.I am trying to find things to enhance my web site!I assume its ok to use a few of your ideas!!

Excellent post. I was checking continuously this blog and I am impressed!

Very useful info specifically the last part 🙂 I care for such info a lot.

I was looking for this particular information for a very

long time. Thank you and best of luck.

Thanks

Perfect information