Project Description

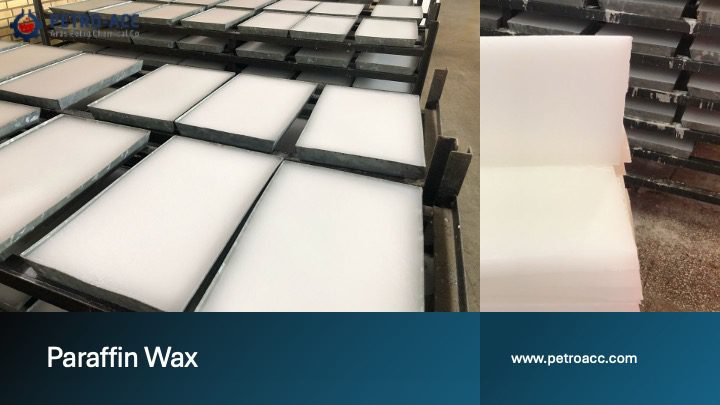

Paraffin wax is a white or colorless, soft, solid substance made from saturated hydrocarbons (alkanes). It is derived from petroleum, coal, or oil shale and is commonly used in a wide range of applications due to its stability, low reactivity, and waxy texture.

| Name | Paraffin Wax |

| Manufacturer | PETRO-ACC |

| Made By | Aras Petrochemical Co |

| Product Code | APW |

PARAFFIN WAX FEATURES

Paraffin Wax Technical Details

Physical Properties

Appearance: White or colorless, translucent solid

Texture: Smooth and waxy

Odor: Odorless or faintly pleasant

Melting Point: Typically between 46°C and 68°C (115°F – 154°F)

Density: Around 0.9 g/cm³

Solubility: Insoluble in water; soluble in ether, benzene, and certain esters

Chemical Properties

Composition: Mixture of saturated hydrocarbons (alkanes), mainly C20–C40

Chemical Stability: Chemically inert and stable under normal conditions

Non-reactive: Resistant to most acids and alkalis

Flammability: Combustible (used in candles and coatings)

Functional Features

Water Resistance: Excellent barrier to moisture and humidity

Electrical Insulation: Good dielectric properties—used in insulation materials

Lubrication: Reduces friction on surfaces

Odor and Taste Neutral: Suitable for use in food and cosmetic applications

Flexibility: Can be blended with other waxes or additives to modify properties

PARAFFIN WAX APPLICATIONS

There are main of applications of paraffin wax, in different industries such as:

Candle Industry

Primary use of paraffin wax worldwide.

Provides a clean, consistent burn and good fragrance retention.

Easily colored and molded into various shapes (pillars, votives, tealights, etc.)

Cosmetics and Personal Care

Used in creams, lip balms, lotions, and ointments.

Acts as an emollient, forming a protective layer that helps retain skin moisture.

Adds texture, smoothness, and gloss to cosmetic formulations.

Used in paraffin wax treatments for softening skin and soothing sore joints.

Food Industry

Used as a coating for fruits (like citrus), cheeses, and candies to prevent moisture loss.

Serves as a moisture and gas barrier for food packaging.

Sometimes used as a release agent or lubricant in food processing equipment (food-grade paraffin only).

Pharmaceutical Applications

Used in ointments and creams as a base or thickening agent.

Provides controlled release in some tablet coatings.

Used in dental waxes and therapeutic heat treatments.

Industrial Uses

Lubrication: Reduces friction in machinery and tools.

Electrical insulation: Acts as a dielectric material in capacitors and other components.

Corrosion protection: Coating for metals, wires, and tools to prevent rust.

Polishes and coatings: Used in floor, furniture, and car polishes for gloss and protection.

Rubber and tire manufacturing: Enhances flexibility and prevents cracking.

Packaging and Paper Industry

Used to coat paper, cardboard, and corrugated materials for water resistance.

Improves strength and durability of packaging materials.

Common in food wrappers, cups, and disposable containers.

Art, Crafts, and Education

Used in batik art (wax-resist dyeing) and crayon production.

Serves as a mold-release agent for casting and ceramics.

Used in wax modeling and sculpting due to its smooth texture.

Energy and Other Specialized Uses

Acts as a phase-change material (PCM) for thermal energy storage—absorbs and releases heat efficiently.

Used in fire logs and ignition materials.

Blended with microcrystalline wax or synthetic waxes for custom performance.

PARAFFIN WAX FORMULATION

Basic Composition

Paraffin wax is primarily composed of:

Normal alkanes (CnH₂n+₂) — typically C20 to C40 hydrocarbons.

Derived from petroleum refining, coal, or shale oil.

Melting point: 46–68°C (varies by grade).

Typical Paraffin Wax Formulations by Application

PARAFFIN WAX STORAGE

1. General Storage Conditions

| Parameter | Recommended Condition / Note |

|---|---|

| Temperature | Store below 35°C (95°F) to prevent softening or deformation. |

| Melting Point Range | Typically 46–68°C (avoid exposure to heat sources above this). |

| Storage Area | Cool, dry, well-ventilated area away from direct sunlight or open flames. |

| Humidity | Keep in a low-humidity environment to prevent condensation or surface oxidation. |

| Containers | Store in sealed bags, drums, or cartons made of non-reactive materials (plastic, metal, or waxed paper). |

| Stacking | Do not stack too high — excessive weight can deform blocks or slabs. |

| Distance from Heat Sources | Maintain at least 1 meter distance from heaters, boilers, or hot surfaces. |

2. Safety Precautions

-

Flammability:

-

Paraffin wax is combustible (flash point ~199°C / 390°F).

-

Keep away from open flames, sparks, and hot surfaces.

-

Avoid smoking in storage areas.

-

-

Ventilation:

-

Ensure adequate ventilation to prevent accumulation of fumes if wax is melted nearby.

-

-

Static Electricity:

-

Ground equipment during transfer of melted wax to prevent static discharge.

-

-

Spill Response:

-

Allow spilled wax to solidify, then scrape and clean with a suitable solvent.

-

Avoid washing molten wax into drains.

-

3. Handling Guidelines

-

During Melting:

-

Use temperature-controlled heating; do not exceed recommended melt point by more than 10–15°C.

-

Indirect heating (water or oil bath) is preferred over direct flame.

-

-

Personal Protection:

-

Wear heat-resistant gloves, eye protection, and long sleeves when handling hot wax.

-

Use respiratory protection if fumes or smoke are generated during heating.

-

4. Shelf Life and Stability

| Property | Detail |

|---|---|

| Shelf Life | At least 2 years, often much longer if stored properly. |

| Chemical Stability | Very stable — resistant to oxidation, acids, and alkalis. |

| Signs of Deterioration | Discoloration, surface oxidation, or odor changes (rare under normal storage). |

5. Transportation Notes

-

Classified as non-hazardous for transport under most regulations (UN classification: Not regulated).

-

Transport in covered vehicles to protect from heat and moisture.

-

Ensure containers are securely closed and upright to avoid leaks.

PARAFFIN WAX PACKING

Paraffin Wax Packing covering different types of packaging, labeling, handling, and shipping practices for industrial and commercial use

1. Common Forms of Paraffin Wax for Packing

| Form | Description | Typical Weight / Size |

|---|---|---|

| Slabs / Blocks | Solid rectangular pieces, easy to stack and transport | 5 kg, 10 kg, 25 kg blocks |

| Granules / Pellets / Pastilles | Small bead-like form, easy to melt and dose accurately | 25 kg bags or sacks |

| Liquid (Molten) Wax | Supplied hot in insulated containers for industrial users | 200 kg drums, 1,000 L IBCs |

| Flakes / Sheets | Thin layers for cosmetic and lab use | 20–25 kg cartons or bags |

2. Typical Packaging Materials

| Packaging Material | Purpose / Benefit |

|---|---|

| Polyethylene (PE) Bags / Liners | Moisture-proof and non-reactive; prevents contamination |

| Carton Boxes | Protects wax blocks or granules; easy handling |

| Plastic or Steel Drums | For molten or liquid paraffin wax transport |

| Paper / Kraft Sacks (with PE lining) | Used for pellets or granules; breathable yet protective |

| Wooden or Plastic Pallets | Used for stacking multiple cartons or sacks; aids transport and storage |

3. Standard Packing Configurations

-

Solid Blocks / Slabs:

-

Each block wrapped in poly film or waxed paper.

-

Packed in cartons or woven bags.

-

Typically 25 kg net per carton/bag.

-

-

Granules / Pellets:

-

Packed in multi-layer paper bags with inner PE lining.

-

25 kg or 50 lb net weight.

-

-

Liquid Wax:

-

Filled hot into 200-liter steel drums or 1,000-liter IBC totes.

-

Must be sealed tightly to prevent oxidation or contamination.

-

4. Labeling Requirements

Each package should be clearly labeled with:

-

Product name: Paraffin Wax

-

Grade / Type (e.g., Fully Refined, Semi Refined, Food Grade)

-

Melting point range (°C)

-

Net weight and batch number

-

Manufacturer’s name and contact details

-

Storage and handling instructions (e.g., “Store in a cool, dry place away from heat and flames.”)

-

Country of origin

-

For export: HS Code (e.g., 2712.90)

5. Transportation and Handling

-

Mode of Transport: Land, sea, or air (non-hazardous cargo).

-

Precautions:

-

Protect from direct sunlight and rain.

-

Avoid excessive stacking pressure.

-

Keep packages upright and intact to prevent deformation.

-

-

Temperature Control: Transport below melting point; use insulated containers for molten wax.

6. Export Packaging (for Bulk Shipments)

| Form | Export Packing Option | Notes |

|---|---|---|

| Solid Blocks | 25 kg cartons on wooden pallets, shrink-wrapped | Most common export form |

| Granules | 25 kg bags, 40 bags per pallet (1 ton) | Easy handling and melting |

| Liquid | ISO tanks or IBC totes | For large-volume industrial users |

-

Standard pack size: 25 kg per carton or bag

-

Protection: Moisture-proof, heat-resistant materials

-

Labeling: Must comply with GHS / export regulations

-

Storage & transport: Cool, dry, well-ventilated, away from heat sources

PARAFFIN WAX SPECIFICATION

| NO | CHARACTERISTIC | APW 201 | APW 202 | APW 203 | APW 204 | METHOD |

| ACCEPTED LIMIT | ||||||

| 1 | Color (Lovibond) | 0.3-0.5 | MAX 0.3 | MAX 0.5 | 0.1 – 0.3 | IP 17 Method A cell |

| 2 | Sp. gravity @ 25 °C | 0.78 – 0.82 0.78 – 0.85 0.78 – 0.85 0.82 – 0.84 | ASTM D 1298 | |||

| 3 | Oil content (% wt) | ≤ 2 1 – 3 3 – 5 0.5- 1.5 | ASTM D 721 | |||

| 4 | Viscosity @ 100 (cst) | 6-8 | 6 – 8 | 6 – 7 | 3.8 – 4.2 | ASTM D 445 |

| 5 | Congealing Point (°C) | 63-68 62 – 68 62 – 65 57 – 60 | ASTM D 938 | |||

| 6 | Penetration 0.1 mm @ 25 °C | 10-30 | 10 – 35 | 30 – 40 | 10- 20 | ASTM D 1321 |

| 7 | Flash point (°C) | MIN 250 | Min 240 | Min 230 | 190 – 210 | ASTM D 92 |

| 8 | Acidity & Alkalinity | PASSED | BP 2020 | |||

| 9 | Drop melting point (°C) | 65-70 | 65 – 70 | 60 – 68 | 60 – 62 | ASTM D 127 |

Leave A Comment